Why it Matters

Transferring potency assays is a complex but crucial process in the development and manufacturing of biological products, particularly in the realm of cell and gene therapies (CGTs). These assays play a vital role in ensuring product efficacy, quality, and stability. Unlike biosafety assays, potency assays must be specifically designed for each product, making their transfer process highly specialized.

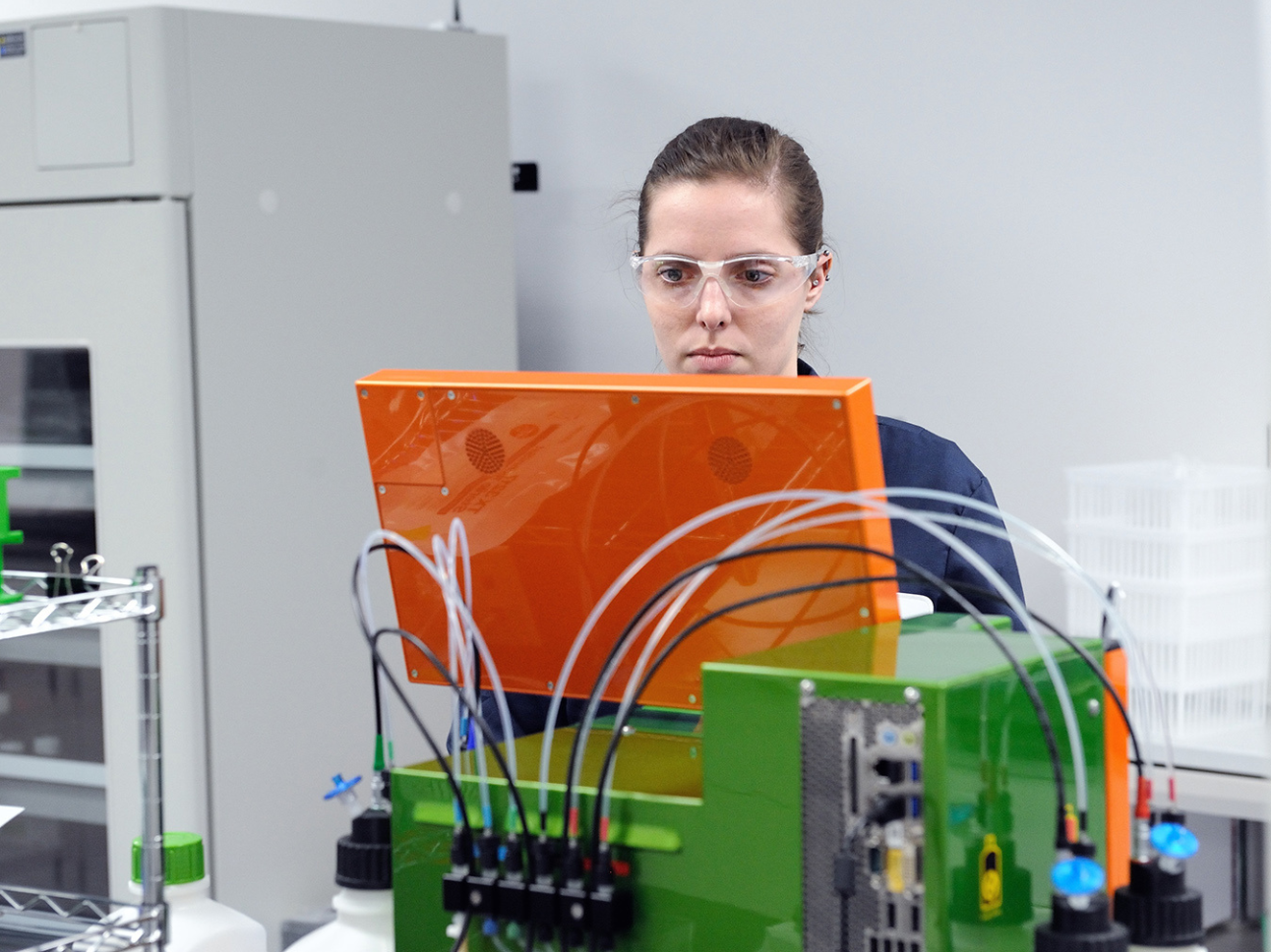

As a Contract Development and Manufacturing Organization (CDMO), WuXi Advanced Therapies has extensive experience in handling assay transfers from a wide variety of sources at various stages of development. To ensure a seamless transition, we have identified five key factors that can significantly impact the success of potency assay transfers.

Five Key Considerations for Potency Assay Transfers

1. Timeframes

Establish realistic timeframes that balance speed and quality.

Setting achievable timelines is essential for a successful potency assay transfer. Factors such as standard operating procedures (SOPs), training, scaling, documentation, equipment validation, and regulatory implications must all be considered. Later-phase or commercial potency assays may require additional qualification and validation. Involving key stakeholders and subject matter experts from both parties ensures a well-informed timeline that aligns with project goals.

2. Agreements

Define clear agreements with detailed scopes and documented expectations.

Each potency assay transfer is unique, requiring a well-documented collaboration between involved parties. Work Orders (WOs) and Master Service Agreements (MSAs) should outline roles, deliverables, pricing, payment terms, and intellectual property concerns. Clearly documenting changes and amendments throughout the transfer process fosters transparency and accountability.

3. Training

Implement a comprehensive training plan tailored to varying experience levels.

Potency assays rely on diverse scientific technologies that require specialized training for GMP laboratory execution. Hands-on training, documentation reviews, and trainer-to-trainer sessions are all crucial components. You can improve knowledge transfer and consistency in execution by adopting flexible training approaches, such as on-site training by expert trainers or laboratory scientists visiting the originator lab. Establishing clear acceptance criteria and performance assessments will help ensure your training programs are effective.

4. Material Readiness

Secure critical reagents and establish a robust sourcing strategy.

Supply chain disruptions can significantly impact potency assays, affecting clinical and commercial product timelines. Early planning for sourcing essential reagents and qualifying suppliers can mitigate these risks. Additionally, in-house production of critical assay reagents, such as reference controls, ensures a steady supply and minimizes delays.

5. Communication

Develop a structured communication plan with escalation paths and regular updates.

Transparent, proactive communication is key to successful potency assay transfers. Establishing a clear cadence of meetings for cross-functional teams and stakeholders helps address potential issues in real-time. A well-documented communication plan, including escalation paths and communication trees, prevents misunderstandings and ensures smooth knowledge transfer.

The Bottom Line

Transferring potency assays is a critical step in the development and manufacturing of biological products, especially for CGTs. Ensuring success requires careful planning, clear agreements, effective training, proactive material readiness, and structured communication. By addressing these five key considerations, organizations can streamline potency assay transfers, minimize risks, and enhance overall product quality and regulatory compliance. As an experienced CDMO, we are committed to supporting seamless potency assay transfers for clinical and commercial success. Contact us today to discuss the future of your program.

Where Can I Learn More?

If you’d like more insight into improving your approach to tech transfer of a cell potency assay or potency assay development, Dr. Audrey Chang, Executive Director and CMC Scientific Advisor and Joseph Newcome, Senior Director, Analytical Development, recently hosted a webinar in which they discussed how to overcome the challenges the industry faces when developing potency assays for cell and gene therapies. You can watch the full webinar or contact us to speak with our experts directly.