Gene therapy represents a frontier in medical science, offering the prospect of cure for previously incurable genetic disorders. Central to this promise are adeno- associated virus (AAV) vectors, the vehicles for delivering therapeutic genes to patients’ cells. However, the commercial success and accessibility of gene therapies hinges on overcoming significant challenges in scalability and testing.

The Scalability Challenge in AAV Manufacturing

The scalability challenge in AAV manufacturing is a critical bottleneck hindering the wider application and commercial viability of gene therapies. Traditional AAV production methods are associated with low yields and recoveries, making the process expensive and inefficient. These challenges stem from the complex biological requirements for AAV vector production, including the need for specific helper viruses and the intricate balance of conditions required for effective replication and packaging of the therapeutic gene. As demand for gene therapies grows, the industry grapples with how to scale up production without compromising quality or increasing costs prohibitively. This situation creates barriers to patient access and places significant financial and logistical strain on healthcare systems worldwide, emphasizing the urgent need for innovative solutions to enhance scalability and reduce the overall cost of gene therapy manufacturing.

We have repeatedly heard from industry veterans that AAV production using the triple transfection system is not a logical fit for affordable gene therapy access for patients or feasible gene therapy manufacturing at scale for drug developers. The gene therapy sector has been on a mission to pursue a game changing solution.

Weimin Valenti – Executive Director of Strategic Alliances and Licensing, and TESSA franchise leader at OXGENE, a WuXi Advanced Therapies company.

The WuXi Advanced Therapies Solution

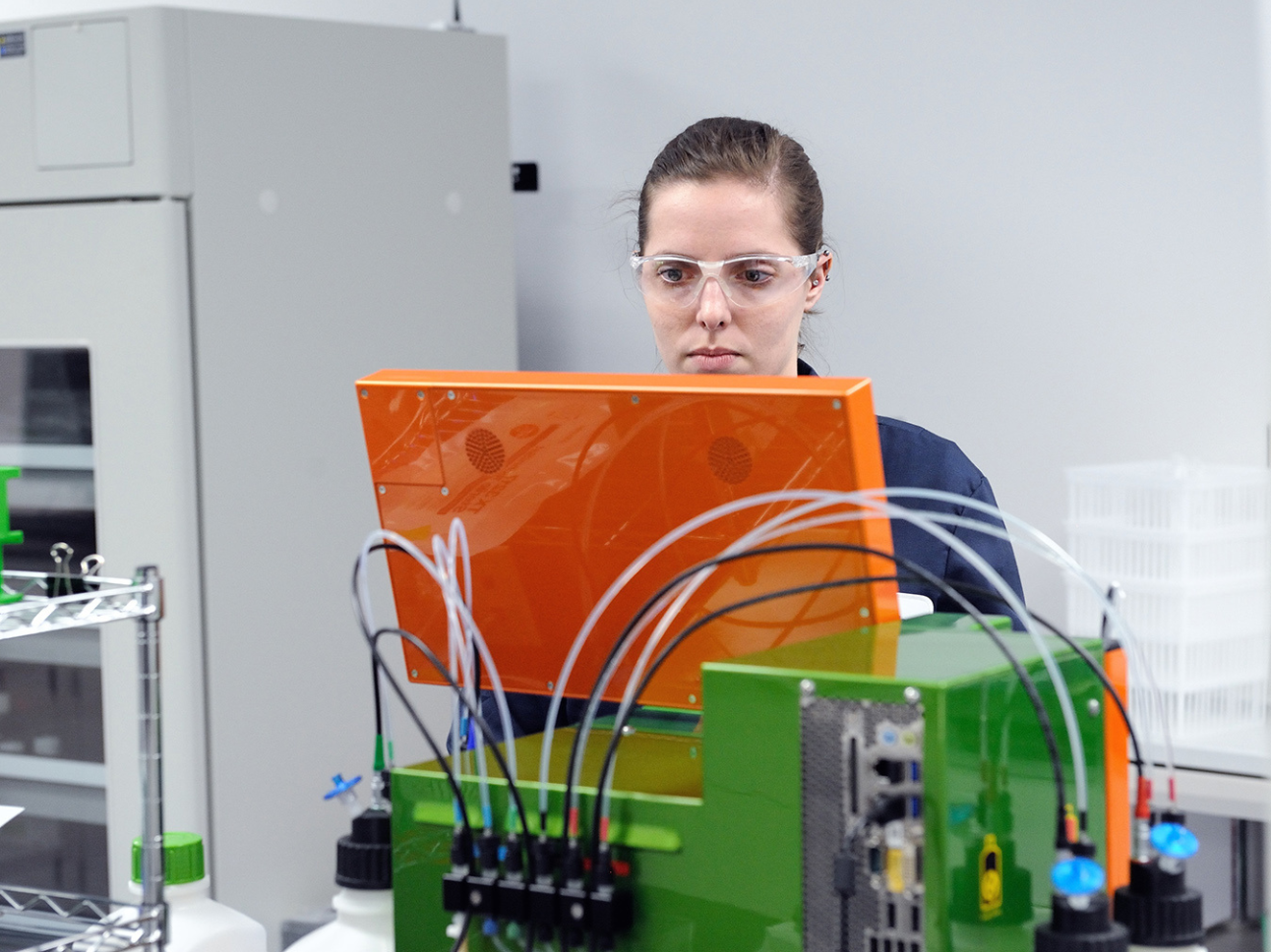

At WuXi Advanced Therapies we have developed Tetracycline- Enabled Self-Silencing Adenovirus (TESSA®) technology, a ground-breaking approach to AAV manufacturing. TESSA® technology transforms the process by enabling transfection-free, scalable production of AAV vectors at Good Manufacturing Practice (GMP) grade in HEK293 cells. This innovative solution significantly reduces costs and complexity, ensuring adenoviral contamination-free AAV production, with patient safety enhanced through the self-silencing of helper adenoviruses. With TESSA®, overall yields can increase more than tenfold due to the combination of improved yield with a significantly higher percentage of full AAV capsids.

TESSA® Pro, an advanced version of this scalable AAV production process, delivers substantial improvements in AAV manufacturing by lowering levels of host cell DNA and reverse packaging contamination. This benefit is evidenced by a study that was completed by Bridge Bio and shared during a webinar conducted in October of 2023 titled ‘Alleviating production bottlenecks in AAV manufacture via platform innovation’ (insights. bio). In practical terms, the TESSA® Pro process has generated up to 23 times more AAV material compared to the 3-plasmid process, with final AAV material quality also favoring TESSA with 100% full capsids versus 51% from the 3-plasmid process.

Recognizing the benefits of the TESSA® technology, Janssen Biotech, Inc., now Johnson & Johnson (J&J) Innovative Medicine, recently entered into a licensing agreement with WuXi and have successfully implemented the TESSA® process, from cloning and virus vector recovery to AdV and AAV production.

Major advance over the state of the art, and competitive in that respect with the best Sf9 platform yields I’ve seen. All in all, my conclusion is that TESSA is a strong contender for anyone considering development of a scalable AAV platform.

Gene therapy expert from a leading pharmaceutical company.

A Partner in Innovation

At WuXi Advanced Therapies we integrate our innovative AAV manufacturing with a comprehensive development and testing platform. By linking process development, assay development, biosafety testing, viral clearance, and product release testing with manufacturing, we ensure the quality and safety of gene therapies. This seamless integration of advanced testing methodologies from early development through to commercialization is crucial for meeting regulatory standards at scale, effectively bridging the gap between scalable production and the market’s demand for safe and effective gene therapies.

Our ethos is to work in close collaboration with our customers, partnering with pharmaceutical and biotech companies to foster innovation in gene therapy. This collaboration extends beyond transactional service provision, addressing industry- wide challenges and pushing the boundaries of gene therapy development and commercialization. Through these partnerships, we leverage our extensive expertise and cutting- edge technology to help bring transformative gene therapies to market, reinforcing our role as a strategic ally in the quest for novel treatments.

Looking Forward: The Future of Gene Therapy Manufacturing and Testing

The future of gene therapy manufacturing and testing is poised for transformative changes. Innovative technologies, changes in the regulatory environment, and the drive towards personalized medicine are expected to shape the landscape. WuXi Advanced Therapies is at the forefront of these developments, ready to lead with ground-breaking solutions that meet the sector’s evolving needs. Our commitment to innovation ensures we will continue to play a pivotal role in advancing gene therapy, making treatments more accessible and effective for patients worldwide.

As we progress through this transformative era of personalized medicine and gene therapy, adopting technological advancements for scaling up manufacturing of these innovative drugs will be critical for their success, and also expand their reach to more patients. TESSA is a breakthrough and built from decades of cumulative virology research, from Atchison’s first identification of AAV particles as contaminants in adenovirus preparations in 1965, to the significant efforts by veterans such as Muzyczka, Samulski, Xiao, Gao, and Grimm, in vectorizing AAV and their attempts to exploit its natural helper, the adenovirus, in generating these efficient gene delivery particles.

Weiheng Su, Head of AAV at WuXi Advanced Therapies and inventor of TESSA technology

We believe TESSA is a significant game-changer for manufacturing AAV medicines, more economically, and help propel them to the clinic and patients.

In Conclusion

Overcoming scalability and testing challenges is crucial for the broader accessibility and efficacy of gene therapies. At WuXi Advanced Therapies we tackle these challenges head on, offering innovative solutions and partnerships to navigate the complexities of gene therapy development and commercialization. Our work not only advances the field but also promises a future where treatments are more readily available to those in need. Partner with WuXi Advanced Therapies to leverage our expertise and technology for the betterment of healthcare outcomes worldwide. Get in touch today and we’ll arrange a time for you to meet with our scientists to learn more. You can also download a copy of this article.